Discover the Versatile Use Membrane Layer Switch Over in Modern Electronic Devices

In the world of contemporary electronics, the application of membrane layer buttons is incredibly substantial, spanning from streamlined customer gadgets to crucial clinical gadgets. These thin, flexible user interfaces not just improve device procedure with their tactile responsiveness but additionally dramatically improve toughness by standing up to ecological risks like dampness and dirt. As sectors remain to progress, the integration of membrane layer switches in tools style is pivotal, promising not just to meet yet surpass the rigorous needs of both functionality and visual appeal. Discover more regarding how these elements are forming the future of technology.

Exploring the Duty of Membrane Changes in Consumer Electronic Devices

Why are membrane switches so common in customer electronic devices? Membrane layer switches are cost-effective to manufacture, making them an appealing option for high-volume production normal in customer electronic devices.

In addition, these switches are understood for their toughness and low maintenance. From microwave stoves to remote controls, membrane switches give a functional, straightforward interface that sustains the dynamic nature of customer electronic devices.

Membrane Layer Changes in Medical Instruments: Enhancing User User Interfaces

Membrane buttons additionally play a considerable function in the world of medical gadgets, where they boost customer interfaces with their distinctive benefits. The smooth, sealed surface of membrane switches enables for simple sanitation, reducing the danger of contamination and spread of microorganisms.

Membrane layer buttons likewise add to the sturdiness of medical devices. Their resistance to liquids and impurities guarantees that vital equipment remains functional in different scientific settings, including surgical treatments where direct exposure to fluids is common. This durability, paired with responsive feedback and inconspicuous style, makes membrane layer changes an integral part in enhancing the efficiency and safety and security of clinical device user interfaces.

The Influence of Membrane Layer Switches Over on Industrial Tools Style

In the realm of commercial equipment style, the incorporation of membrane layer buttons has noted a significant development. These buttons have changed exactly how suppliers approach individual interface capabilities, providing a mix of resilience and convenience that is necessary in severe settings. The slim profile of membrane switches Going Here over permits for more small maker layouts, while their resistance to water, chemical, and dirt pollutants makes them excellent for industrial setups. This versatility has actually promoted the development of equipment that is not only a lot more durable but also much easier to keep and tidy, thereby decreasing downtime and operational expenses.

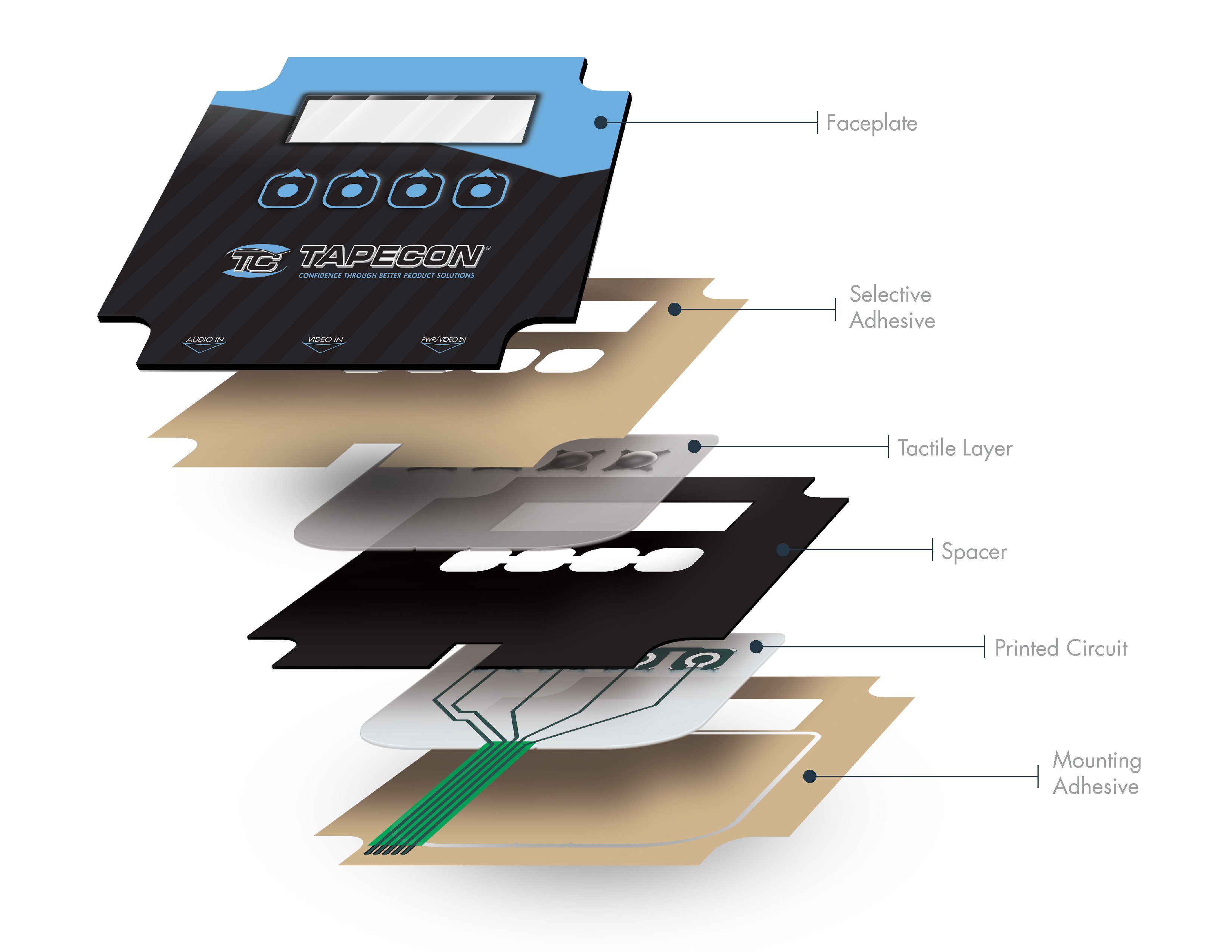

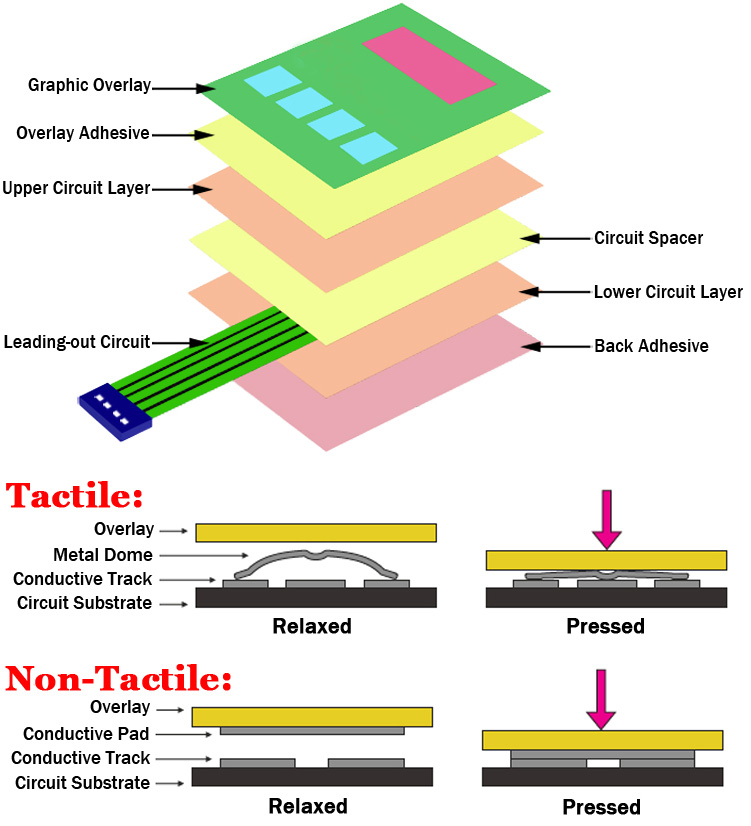

Additionally, the customizability of membrane switches over makes it possible for developers to incorporate certain responsive comments and graphical overlays that enhance the user experience and rise performance. This assimilation sustains operators in achieving accuracy control over intricate equipment. The general impact is a significant improvement in the capability, dependability, and user-friendliness of industrial equipment, straightening with the boosting demands for technological innovation and functional effectiveness in modern sectors.

Final Thought

Membrane buttons have actually transformed contemporary electronics, providing sleek, sturdy, and personalized user interfaces across numerous markets. Membrane Switch. In consumer electronic devices, they improve the visual and performance of devices. Clinical markets benefit from their trustworthy, straightforward controls, important for delicate environments. Similarly, commercial applications value their resilience and effectiveness. This modern technology not only fulfills the demanding problems of various fields yet also dramatically enhances customer experience, making these details membrane switches over a cornerstone of contemporary digital design.

In the realm of modern electronics, the application of membrane layer buttons is extremely comprehensive, extending from sleek consumer devices to crucial medical gadgets.Why are membrane layer changes so widespread in customer electronics? Membrane buttons are cost-effective to page produce, making them an eye-catching alternative for high-volume manufacturing regular in customer electronic devices. From microwave ovens to remote controls, membrane switches offer a functional, straightforward user interface that sustains the dynamic nature of customer electronic devices.